Mining underpins the global economy, supplying the raw materials that drive industrial production, energy generation, and infrastructure development. As resource constraints become increasingly evident, the industry’s focus has shifted from maximizing extraction volumes to improving operational efficiency, traceability, and decision accuracy. This shift has accelerated the adoption of RFID-enabled technologies that provide real-time visibility into assets, materials, and processes across the mining value chain. By embedding RFID tags in equipment, containers, and ore flows, operators can automate identification, monitor movement and utilization, and integrate high-fidelity data into operational and enterprise systems. The result is improved productivity, reduced material loss, enhanced safety compliance, and more sustainable resource extraction.

We aim to optimise the first run of mineral processing plants by using our proprietary RFID Tracer Auditing solutions. At the heart of our Tracers is Radio-Frequency Identification (RFID) and a centralised monitoring platform for determining and providing real-time mineral extraction efficiency. The tracers, antennas and control system are made with unique RFID tags built and fabricated in-house by CreoX.

Tracers that range in size from as small as 4mm up to 80mm in size have been successfully produced for specific customers and use-cases. See diagram below for tracer depiction.

Advantage of RFID Audits

We have successfully deployed Tracer systems to several mining operations in Southern Africa, and Australia. Improvement in extraction efficacy has been documented and new deployments are currently underway.

RFID Tracers made to various sizes and colours

Process

The variety of mining operations are as wide as the pool of ores, terrains, minerals, and companies involved. Our tracers can be deployed near universally in operations where there are automated ore sorting processes. We have successfully deployed into Diamond, Coal, and Iron extraction operations.

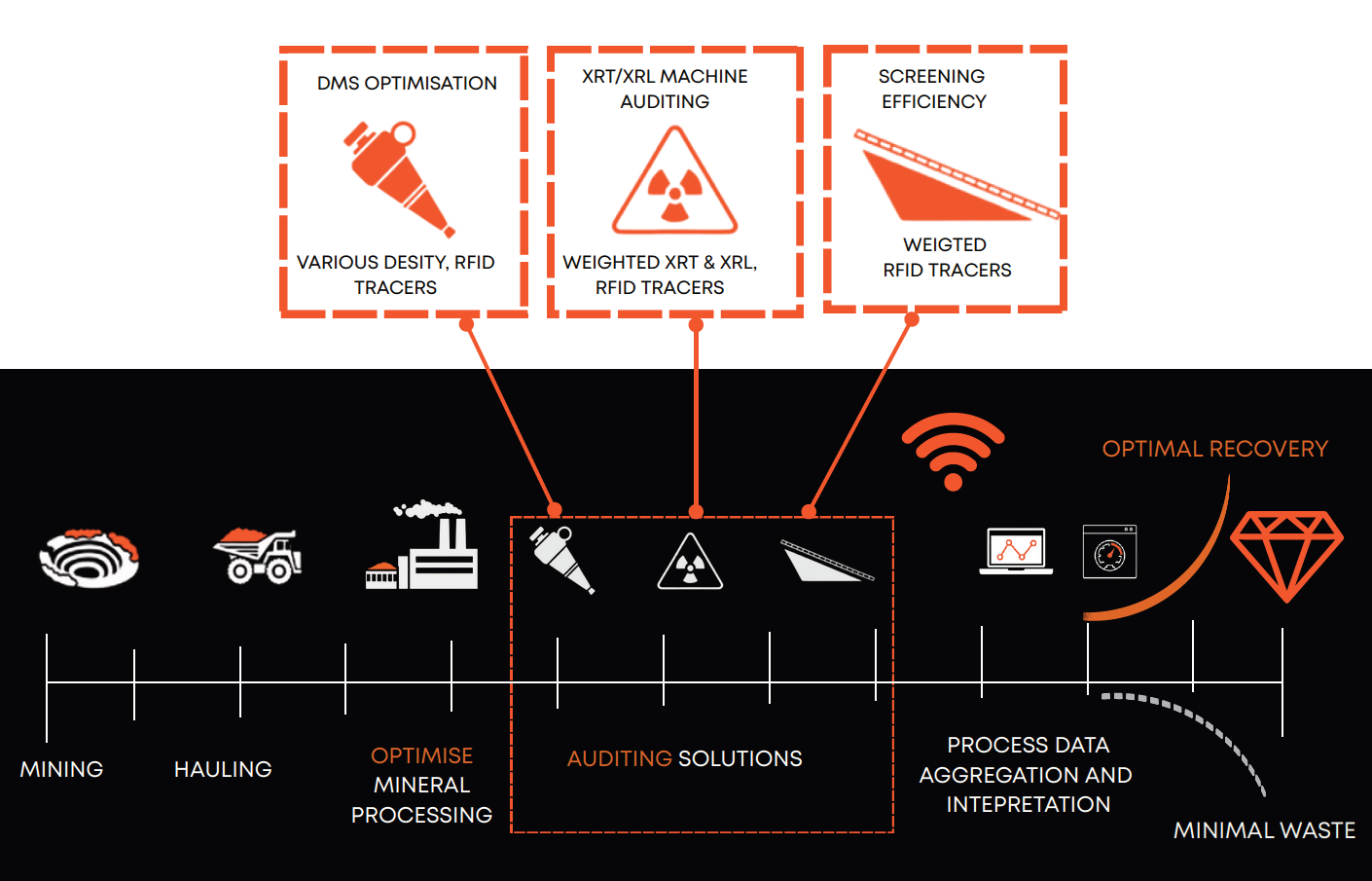

Below is a diagram that indicates where in the mineral extraction process the technology is deployed.

Tracer deployment within the mining process

Simulants

Tracers that mimic various ore properties are called simulants.

RFID Diamond and Coal simulants have been used successfully in collaboration with our customers to improve various aspects of the mining process.

Sorting methodologies

Controlled quantities of tracers are deployed at the ingress of the processing plant along with the mineral-rich ore. The sorting of the tracers occurs alongside the ore, and they end up in either mineral or waste egress locations.

This is possible due to the unique properties of the tracers that simulate the specific mineral. Based on these mineral specific qualities, the ore and tracers are sorted simultaneously, and any false positive or negative sorting events can be identified and corrected.

Method 1: X-ray Transmission (XRT)

X-rays are used to identify material based on their specific atomic densities. When a large enough concentration of a certain transmissibility is detected, a positive identification can be made and the object sorted accordingly. The Tracers are fine tuned to mimic the XRT properties of a mineral and thus can validate or diagnose the XRT sorting process.

Method 2: X-ray Luminescence (XRL)

Similar to XRT, but instead of using the density of the tracer, mimics a diamonds’ glow (luminescence) under x-ray irradiation to confirm or diagnose the XRL sorting process.

Method 3: Dense Medium Separation (DMS)

DMS has historically been successfully used to sort almost every mineral from its surrounding substrate. Various techniques exist, most of which involve liquid suspension or vibration sorting. Generally, a liquid medium that has a density approaching that of the intended extraction target is used. The mineral (and tracers) is added to this liquid and either spun out for collection or suspended between different densities.

Regardless of which DMS technique is employed, tracers are the ideal solution to reach full extraction potential.

Conclusion

As mining operations continue to face increasing pressure to improve recovery rates, reduce losses, and operate more sustainably, RFID-enabled tracer and simulant technologies provide a practical, data-driven path forward. By delivering real-time, process-level insight into sorting efficiency and material flow, the AudeX RFID Tracer Auditing solutions, provided by CreoX, enable operators to move beyond assumptions and static sampling toward continuous, measurable optimisation. The ability to accurately diagnose inefficiencies across XRT, XRL, and DMS processes—using mineral-specific tracers engineered in-house—positions this technology as a critical enabler of first-pass yield optimisation. Ultimately, RFID-based auditing empowers mining companies to extract more value from existing resources, improve plant performance with confidence, and make informed decisions that support long-term operational and environmental sustainability.

For more information, please visit the AudeX website here.

Leave a comment