Through various projects in automotive and military vehicle applications, CreoX fulfilled our customers’ need for an effective real-time vehicle monitoring system to detect faults, signal maintenance requests, and provide the operator with critical system errors.

The CreoX HUMS solution is your vehicle’s guru, that knows everything about your vehicle and keeps track of usage parameters and maintenance schedules. HUMS ensures optimised maintenance intervals, enhanced asset monitoring, and automated logbooks per component.

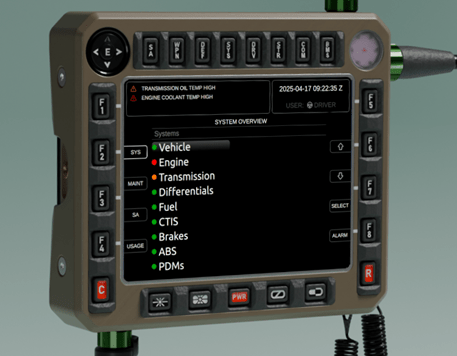

HUMS main interface on a CreoX display

Whether as an add-on to existing vehicle fleets, for vehicle upgrades and modernisation projects, or as part of a new vehicle development, the HUMS is customised according to customer requirements.

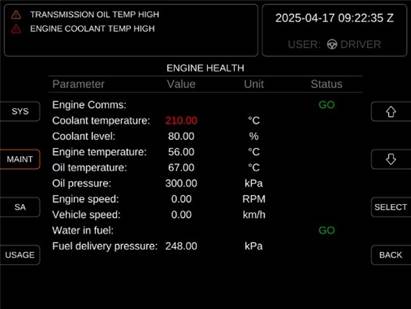

The software platform is suited to perform onboard diagnostics and data logging. This enables users to detect system faults such as excess vibration, abnormal temperatures, loss of communication, to name only a few. These faults are displayed immediately with colour-graded scales for priority identification. They are grouped according to systems such as Engine, Transmission, and other vehicle-specific sub-systems. Each fault reports various details such as system of origin, time, and actionable steps to mitigate risk.

Automated Interval Maintenance

The purpose of a vehicle HUMS is to provide actionable maintenance task alerts with various layers of detection mechanisms. The first layer is to keep track of vehicle parts according to their serial number and track usage time per component. Upon a component reaching its user defined maintenance interval (or end-of-life) the operator is informed via the GUI. It is then the operator and maintenance team’s responsibility to either replace the component or do the required maintenance tasks, such as filter and oil changes. The maintenance activities are then captured on the HUMS database, and serial numbers of replaced items are updated accordingly.

Data-driven Maintenance

The second layer of maintenance augmentation is the monitoring of system characteristics based on known and normalised system behaviour, also known as Anomaly Detection. Traditional warning systems compare readings to a pre-defined safe range and is similar to the warning light on a commercial vehicle, however, the HUMS takes this a step further:

The HUMS makes use of historic data such as temperature and vibration to give real time anomaly indications. On a given system’s sensors, for example an engine, temperature and vibration data are analysed and potential failures

are reported. Statistical methods such as Z-score analysis are used to determine if the present state is abnormal. The model is updated continuously which provides real-time feedback.

GUI

The HUMS GUI is designed to be focused and provide feedback at a glance. There are various screens, each showing a unique level of information such as system list, system detail, warning list, and warning detail amongst others. Below are examples using simulated data.

Notification and warning screen

Engine System Detail Screen

Additional features

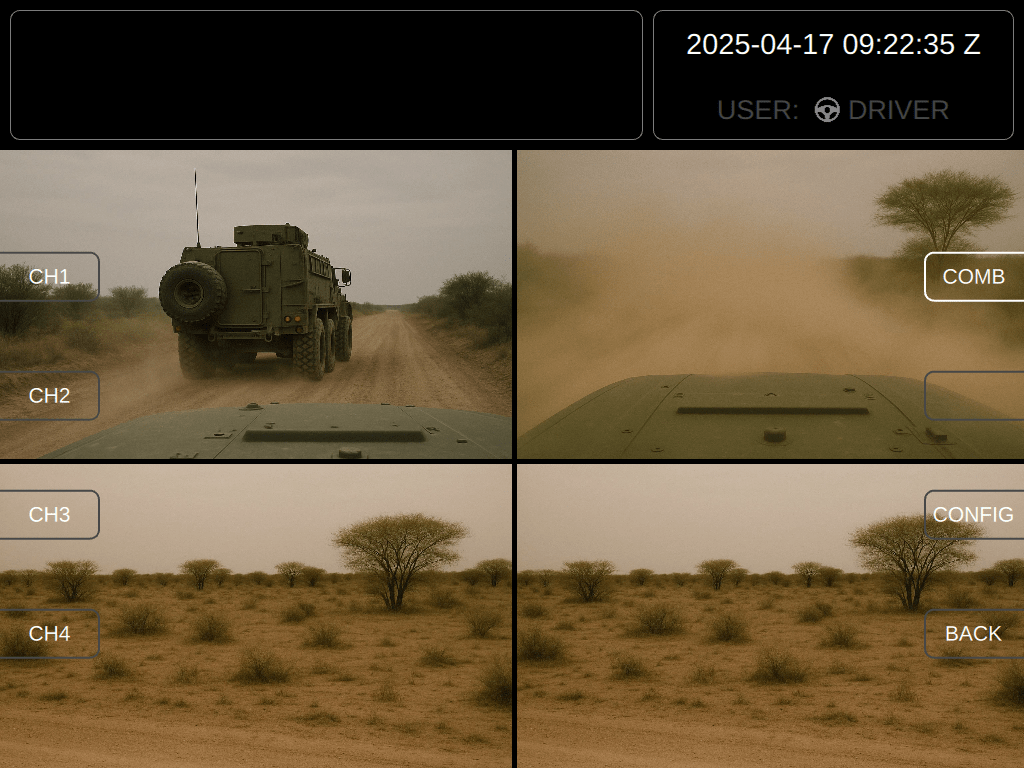

Additionally, the HUMS GUI has been customised for use cases that receive video streams across PAL or Ethernet to allow for visual monitoring and situational awareness. These views are system dependent and fully customisable per specific client requirements such as individual camera, panoramic, or birds-eye view to name a few.

A CBRN (Chemical, Biological, Radiological, Nuclear) detection system has been integrated with the HUMS system via a MODBUS protocol over a serial interface. This demonstrates the capability to integrate with third-party systems and create a modular ecosystem that can centralise warnings and environmental awareness indicators.

HUMS has been successfully mirrored across Ethernet via a DDS protocol, providing a mirrored version across an intra-vehicle network at no extra processing cost. This is useful in a gunner-commander setup within a vehicle to enable a shared digital model of the hardware system that they share.

Situational awareness video screen

The DDS protocol is also used in the NATO Generic Vehicle Architecture (NGVA), which makes the HUMS compatible and able to integrate with NGVA-compliant sub-systems.

For security reasons, the log files generated by the HUMS software cannot be edited by non-admin users. This protects the integrity of the database of maintenance data.

Technical specifications:

- CAN bus integration. Examples of CAN devices: Engine Electronic Control Unit (ECU), Transmission ECU, ABS ECU, third party PDMs (Power Distribution Modules) using J1939 CAN bus standard. Other CAN bus standards can also be integrated and used.

- Multi-user login (default is USER and MAINTENANCE)

- DDS protocol for mirrored data and NGVA-compliant sub-systems

- PAL- and Ethernet-based camera integration

- Influx DB and SQL database implementation

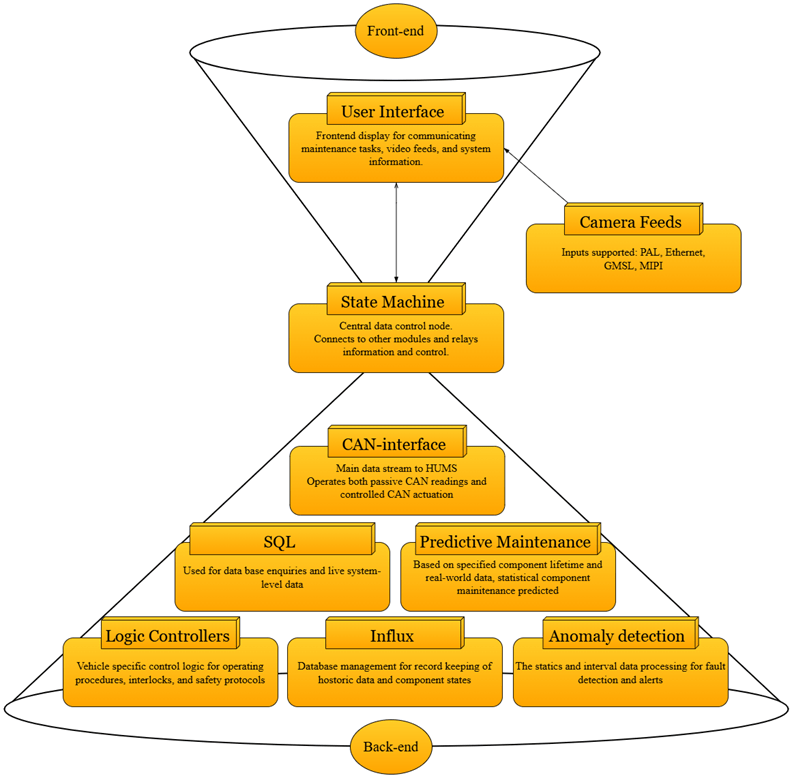

Software architecture

Our platform is designed to be modular and easy to customise according to client needs. The following diagram shows the building blocks of the platform, each of which can be readily activated or deactivated. This allows for client specific versions generated at compile time.

The “hourglass” shape is functional and ensures data integrity and synchronisation via the State Machine. This module handles and regulates the flow of information to all others.

Deployment

Deploying to client hardware is achieved via a custom installation script where the hardware versions are selected and drivers are automatically installed, ensuring reliable and fast deployments.

CreoX offers client specific support for the integration of HUMS with existing systems as well as continued use support and development. Updates are handled efficiently via Ethernet, or serial ports and the HUMS can be deployed for various operating systems and computer architecture.

Further Development and Conclusion

A development goal for the HUMS software platform is to integrate machine learning into the platform to perform another layer of real-time analysis on the data that is gathered. This will move the HUMS into the realm of smart maintenance and artificial intelligence. At present, deployed HUMS systems are in operation and gathering data that will one day be used to train these models.

The HUMS platform allows peak hardware performance and peace of mind for personnel since optimum component conditions are maintained. Read more about the HUMS and other innovations in the following article:

Defence product development trends – is the SA defence industry ready?

Please leave us a comment and subscribe to receive updates whenever a new blog is released!

Leave a comment